Metrô Rio is the second largest metro system in Brazil by passenger volume (behind São Paulo), with 41 stations and 58 kilometers (36 miles) of railway lines. It serves 228.2 million passengers annually. During peak hours, 52 trains operate on the main line, totaling 312 carriages. The Transport Services Department constantly checks and maintains at least 12 such trains and 72 carriages at its maintenance center in Rio.

The time-consuming process of identifying and locating carriages during routine inspections involves workers walking along the tracks to identify their needs, transport them to appropriate maintenance areas, and finally find the necessary tools for their work. Tools could sometimes be borrowed by other workers, making them hard to locate. To efficiently track, identify, and simplify the search for shared equipment among its maintenance team, Metrô Rio sought a solution from Brazilian RFID technology company RFID Brasil. Recalling the team's desire to create a smart cabinet to track the entry and exit times of tools and who owns them, RFID Brasil's business development expert for RFID and IoT, Glaucia Gomes, aimed to establish a solution that would help maintenance supervisors and coordinators optimize their maintenance processes.

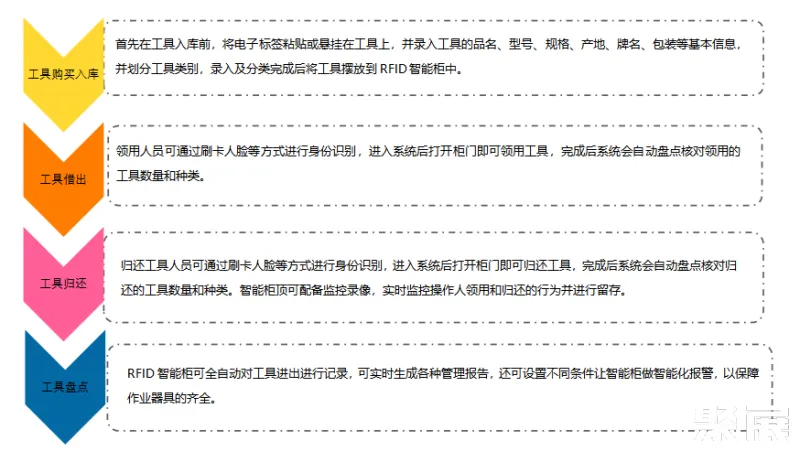

The general process of the smart cabinet in tool managementRFID Brasil applied RFID tags to the tools and built a cabinet with a single RFID reader and an antenna array. A touch screen, an RFID card reader, and a camera recording transactions are located on the front of the cabinet. On the server of the cabinet, RFID Brasil provides software to control and track the use of tools, as well as cloud-based software and applications. For use of the cabinet, each worker has their own ISO 15693 standard compliant HF 13.56 MHz RFID ID card. Initially, they walk up to the cabinet where their card is scanned. The software stores data including which individuals are authorized to access these tools. If authorized, the cabinet door unlocks. The touch screen displays available tools in the cabinet. It also shows checked-out items and the checker. After implementing the RFID smart cabinet, the effects were significant.

With accurate identification of available tools, the transportation company no longer needs to purchase excess assets. The system helps reduce losses by holding workers accountable for the tools they use. If a tool is not returned, management can easily identify who owns it using the software and retrieve it. "We can talk to employees and tell them to be more careful next time," he adds. Workers are now more aware of tool locations and ensure they return them to the cabinet. When workers exchange tools and are not near the cabinet, they can access the RFID Brasil software on their phones to update details about the tool and who is responsible. They can also log into the system application. Additionally, the software features chart analysis functions designed specifically for the solution, displaying which items are used more frequently and which are not used, to help understand what inventory the tools need. Metrô Rio calculated the return on investment (ROI) based on reduced losses and labor costs. "We expect the payback period to be three to four years, which is a very conservative estimate," says the staff member. In the future, the company expects to tag more items, including tools from other departments and keys to warehouses, which are often accidentally taken home at the end of the day.